Structural Packaging Design Your Own Boxes And 3d Forms Pdf

Our Verdict

The Form 3 produces high-quality 3D prints in a variety of materials without fuss, but it is expensive. Artists, designers and professionals who rely on 3D printing will find this cost acceptable for the time it saves, but enthusiasts may seek out cheaper options like SLA printers from Peopoly that can produce similar quality results with tweaking.

For

- Excellent print quality

- Support for range of Formlabs supplied materials

- Supports multiple users and printers

Against

- Expensive

- Use of third-party resin voids warranty

- No major speed increase from older Formlabs models

Tom's Guide Verdict

The Form 3 produces high-quality 3D prints in a variety of materials without fuss, but it is expensive. Artists, designers and professionals who rely on 3D printing will find this cost acceptable for the time it saves, but enthusiasts may seek out cheaper options like SLA printers from Peopoly that can produce similar quality results with tweaking.

Pros

- + Excellent print quality

- + Support for range of Formlabs supplied materials

- + Supports multiple users and printers

Cons

- - Expensive

- - Use of third-party resin voids warranty

- - No major speed increase from older Formlabs models

The Form 3 from Formlabs is a high-end Stereolithographic (SLA) printer that uses a laser to zap liquid resin into solid form. It's a sophisticated printer that can produce excellent quality prints with little maintenance or tweaking, making it a great pick for those who want to do a lot of printing without hassle.

These quality prints don't come cheaply, though — the Form 3 starts at $3,499. That may be a hard price to swallow, especially as rival 3D printer makers developer cheaper SLA models, such as the Peopoly Moai. But budget SLA printers often require a lot of experimentation and maintenance to produce quality prints. The Form 3 requires little of either: It just works. And that's why we include the Form 3 on our list of the best 3D printers you can get right now.

For this review, we tested the $4,999 complete kit that includes the Form 3 printer and the Form Wash and Form Cure devices used for cleaning and finishing prints.

Form 3 3D printer review: Price and availability

Your best bet to buy a Form 3 3D printer is to head directly to FormLabs. There, you'll find the printer available for $3,499 these days, with service plans adding to the cost of your 3D printer.

Since we first reviewed the Form 3 a few years ago, less expensive SLA printers led by the Peopoly Phenom have come out. And while those devices cost a fraction of what you'll pay for the Form 3, the Formlabs printer remains the standard bearer for SLA models.

Form 3 3D printer review: Design

The Form 3 looks much like previous printers from Formlabs, with an orange plastic hood over the printing area and a black plastic base. That's about more than just aesthetics: the UV-blocking orange plastic lets you see what is going on while printing is underway, but without outside lights interfering with the process. This hood folds back to reveal the important parts of the Form 3 — the resin tank and the print platform. Both are a little larger than the previous Form printers, offering a print area of 5.7 x 5.7 x 7.3 inches, or just over 237 cubic inches. A larger model, the Form 3L, ups this to 11.8 x 13.2 x 7.9 inches, a total of 1,230 cubic inches. The Form 3L, which is due to start shipping later this year, will cost you a cool $9,999, though.

We had no failed prints in our Form 3 tests, which is a first for a 3D printer.

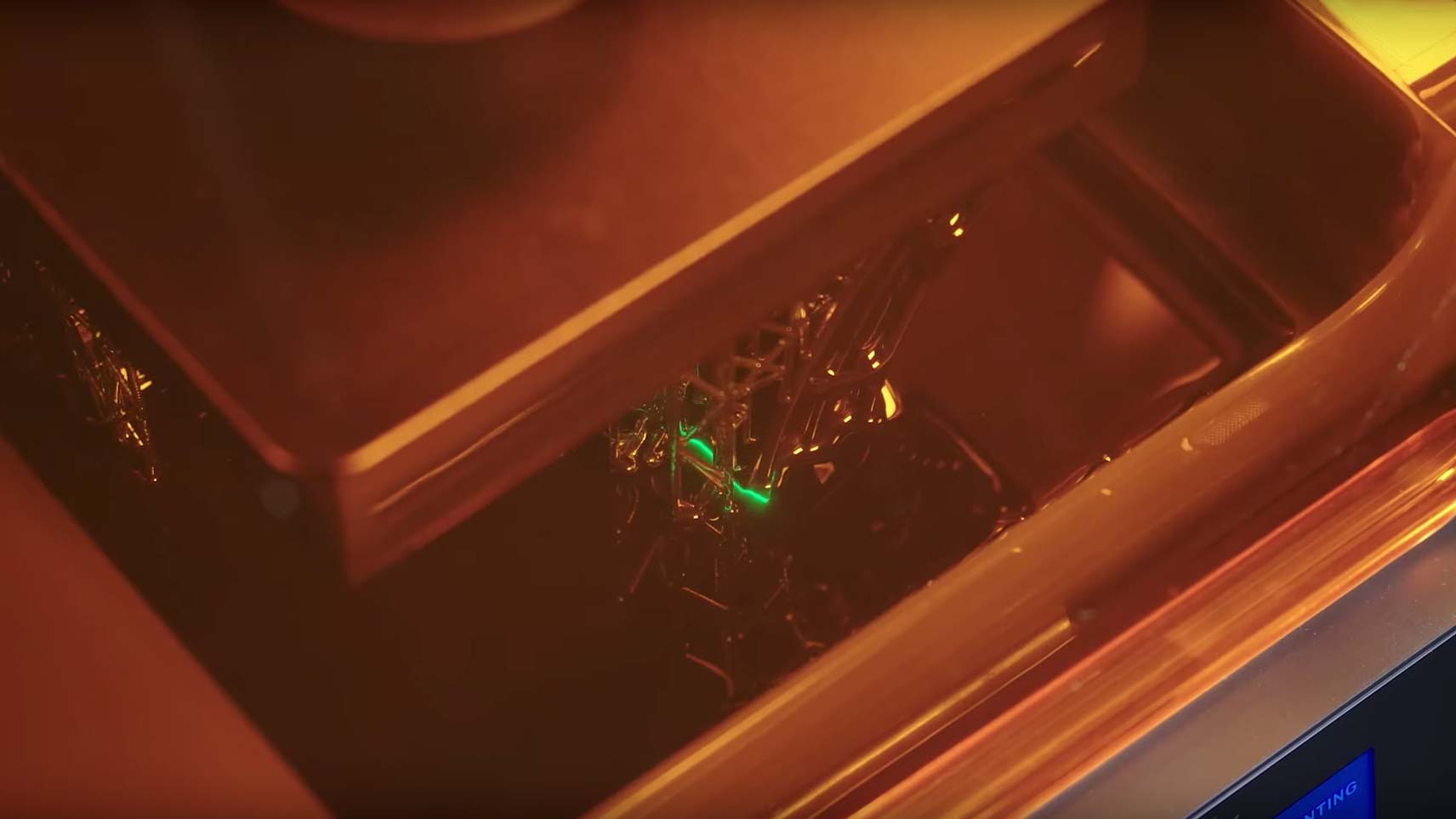

The removable resin tank is where the liquid resin sits during printing. The tank's base features a thin, clear plastic layer that the printing laser shines through. To create each layer of the print, the build platform is lowered down to just over this base layer, trapping a thin layer of liquid resin. The UV laser then zaps the liquid, turning it into solid resin, which sticks to the build platform. The printer then lifts the platform, taking the hardened resin with it. The platform lowers again, trapping another layer of liquid resin, and the process repeats. Thus, the Form 3 creates the print layer by layer with layer heights ranging from 0.1mm down to 0.025mm.

One of the innovations here is the flexible plastic on the bottom of the layer, which means that the Form 3 can use less force in pulling the hardened layers up. Formlabs calls this Low Force Stereolithography, and claims that it makes printing more reliable. Formlabs isn't the first printer maker to use this technique (it's available as an upgrade feature for printers like the Peopoly Moai), but it definitely seems to be effective. We had no failed prints in our Form 3 tests, which is a first for a 3D printer.

The Form 3's laser and optics are found under the resin tank, located in a sealed package called the Light Processing Unit (LPU). This, Formlabs claims, makes the printer more reliable as dust can't get in to block the path of the laser. It also makes the LPU easier to replace, as the whole unit can be easily removed and replaced by the user.

The Form 3 produced excellent quality prints, with fine details and smooth, organic curves and surfaces, even when we used the fastest print settings.

The Resin cartridge in the rear of the Form 3 holds the liquid resin. The printer automatically fills the resin tank: You never need to touch the resin or fill the tank yourself, which is a plus because it is nasty, stinky stuff. The resin tank and cartridge are removable so you can swap out different printing resins without having to clear out the whole printer. The tanks can be cleaned out and reused, but the resin cartridges can't be reused. It is possible to fill a cartridge with a third-party resin, but Formlabs stresses that this might void the warranty of its printer. If you aren't using the printer for a few days, Formlabs recommends that you remove the print tank and store it in the airtight shipping container it came in to prevent it hardening in place.

Form 3 3D printer review: Controls

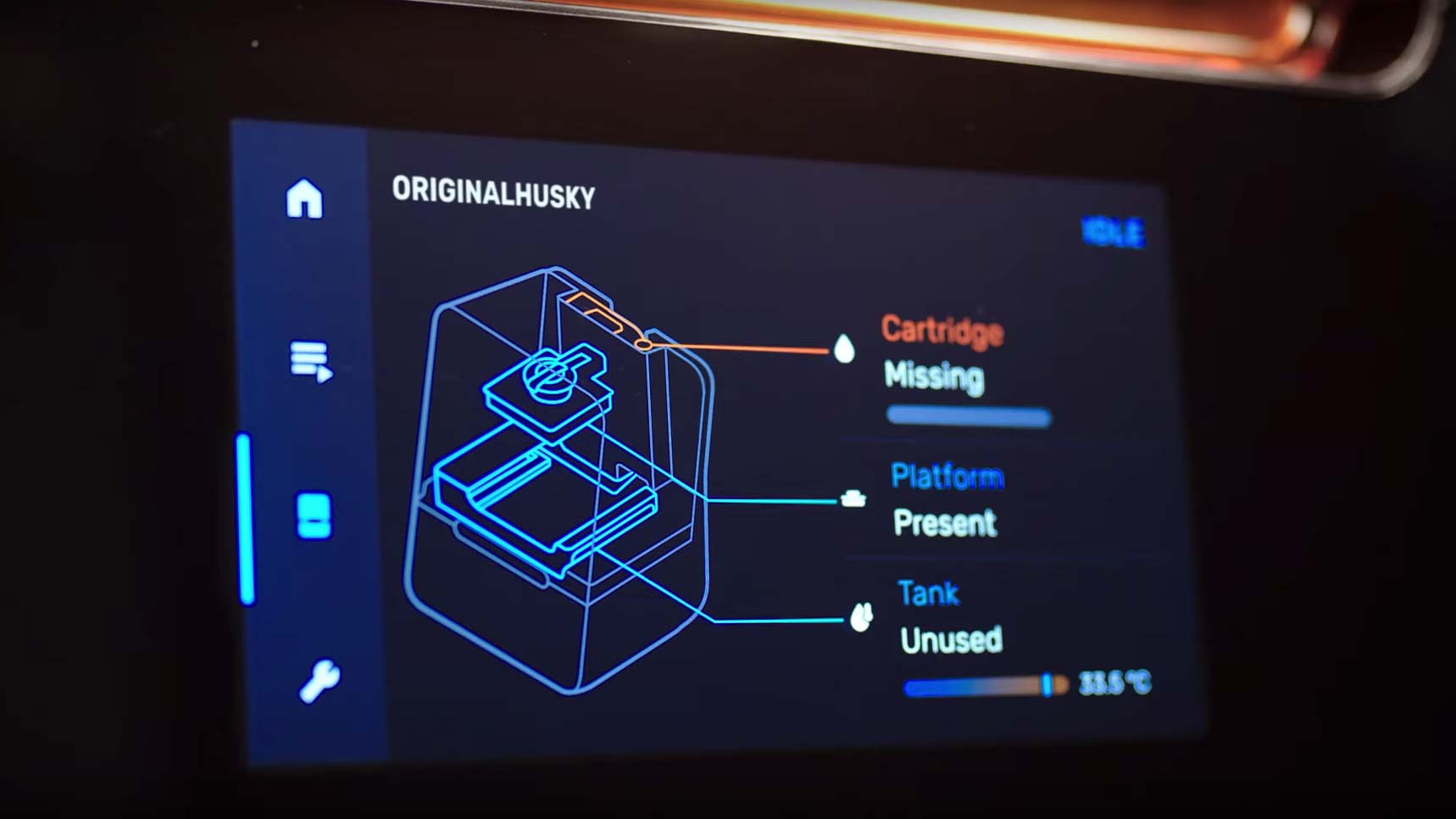

The Form 3 includes an excellent touch screen that allows you to control the printer directly, accessing all of the features and stopping or starting prints. Most users will turn to the PreForm software and the online printing dashboard to operate the Form 3, though.

SLA printers typically require a lot of tweaking, calibration and other fiddling to get good results. The Form 3 just works.

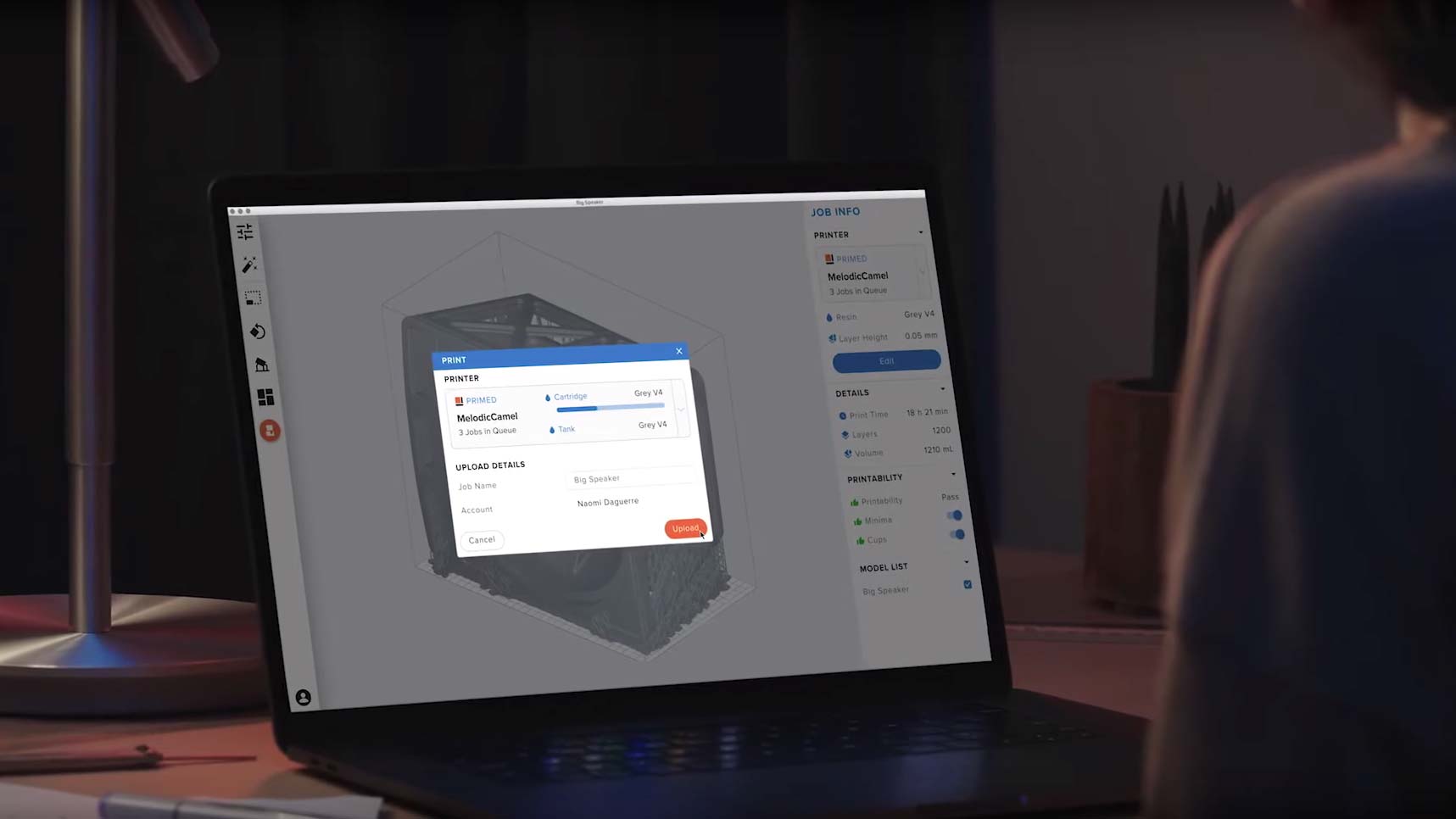

PreForm is the software that prepares your print, loading a 3D model (standard .stl and Wavefront .obj formats are supported) and slicing the model for printing. Available as a free download for Mac and Windows, PreForm is straightforward to use, with a helpful one-touch printing feature that automatically prepares the print, creating the supports that hold it in place while printing and sending the file to the printer. If you want to tweak the process yourself, PreForm allows you to scale, move, spin and otherwise mess with 3D models, as well as arrange several models for printing at one time (a process called plating).

The printing dashboard is an online service that manages the Form 3. It's aimed more at users who operate multiple Form printers or those who share a single printer between multiple users. This dashboard allows you to queue and schedule prints, monitor print progress and pause or cancel printing. The dashboard can also notify you through your cellphone when a print is complete or when a printer has a problem or requires maintenance.

MORE: How to Buy a 3D Printer

Since there's no camera inside the Form 3 to monitor the prints, you generally don't know if a print has failed until it is complete, unless you take a look during the printing process. The Form 3 isn't unique in this, though: The way that 3D printers like this work, with a large print platform obscuring the printing area, makes it harder to see how the print is progressing.

Form 3 3D printer review: Performance

In our tests, the Form 3 produced excellent quality prints, with fine details and smooth, organic curves and surfaces, even when we used the fastest print settings. Our test models had smooth, even detail with barely detectable layers.

Our first test model is a 3D scan of Rodin's The Thinker sculpture. The resulting prints looked excellent. We appreciated the curves on the sculpture's shoulders and arms and excellent detail on its face.

The layers of the print were barely visible, even on the fastest 25-micron printing setting.

With the layer height on the minimum 0.025mm setting, the layers are barely visible on the shoulders of The Thinker.

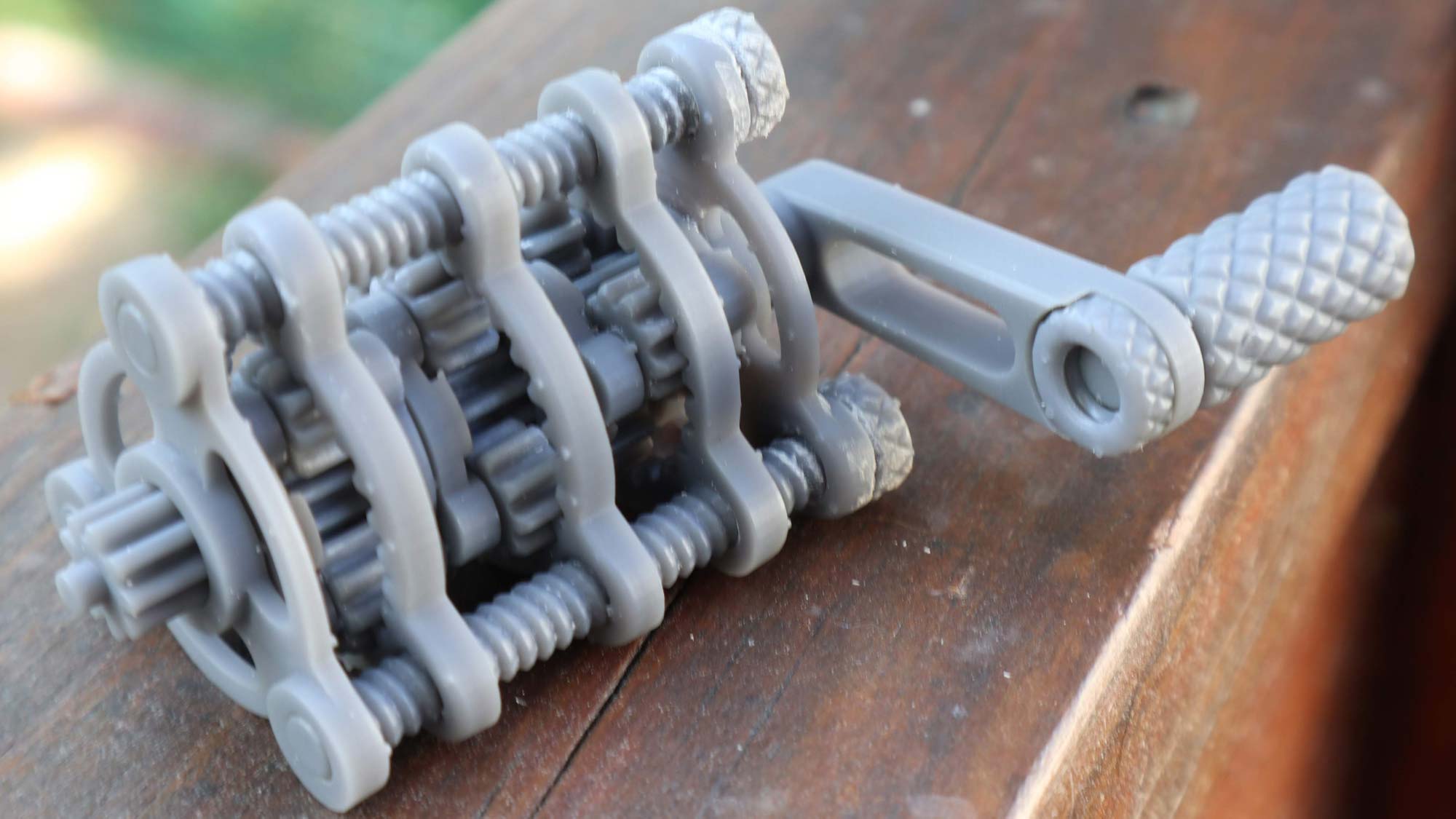

Our second test creates complex set of planetary gears, to see how well the printer can produce interlocking parts. The Form 3 produced excellent quality prints here, too, handling complex details like the screw thread and gear teeth. The parts fit together without any hassle, with screws fitting tightly into other parts and gears meshing together cleanly.

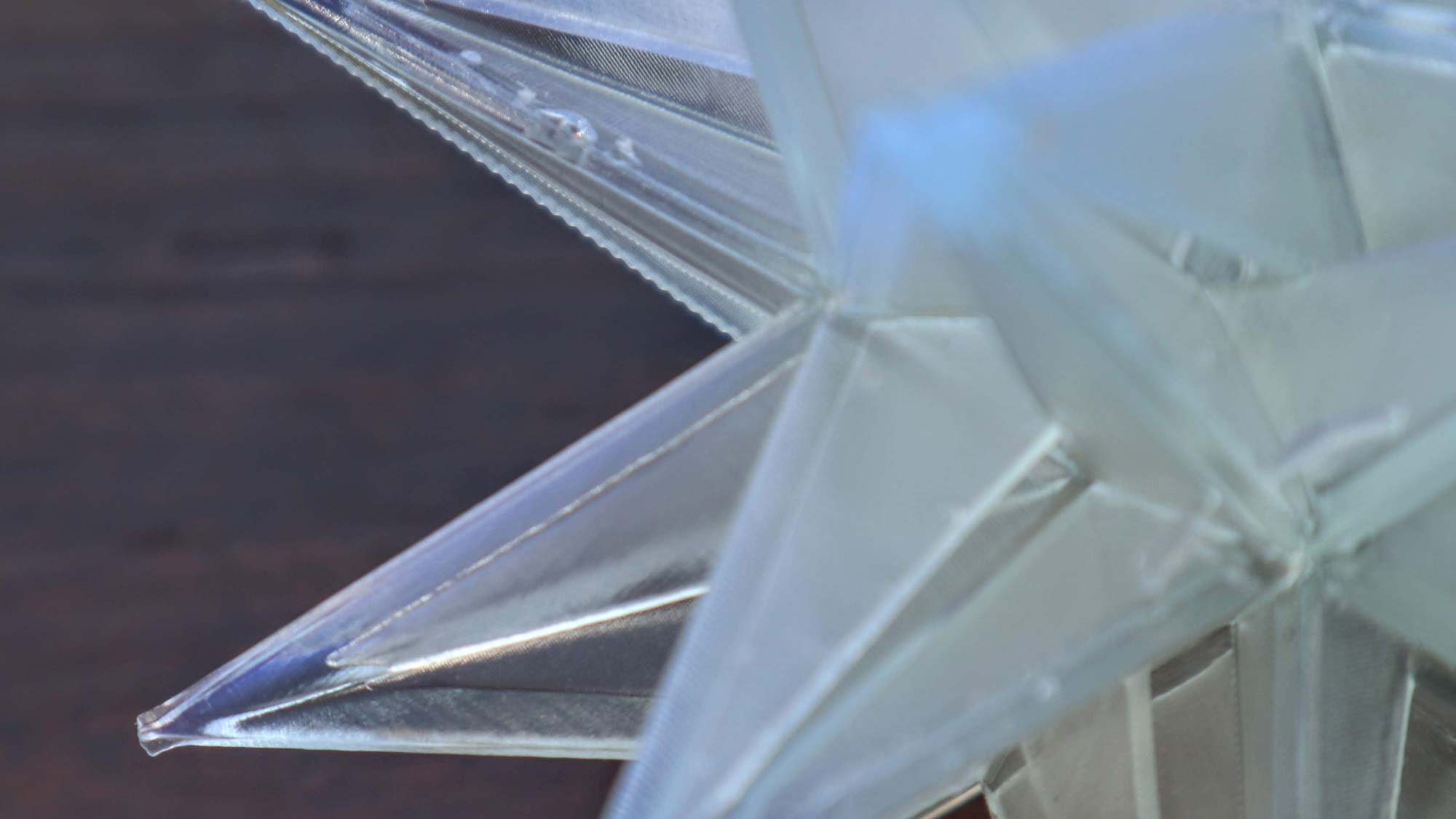

Finally, we use a geometric sculpture as a test of how well the printer can reproduce sharp edges and points. Again, we found excellent results here, with the many angled surfaces of the sculpture coming out with clean, smooth edges and sharp points that almost look like they could draw blood.

Form 3 3D printer review: Speed

The Form 3 is not a particularly fast printer, taking between 10 hours and 17 hours and 21 minutes to complete our standard 4.5-inch Thinker test print, depending on where we set the layer height. SLA printers are not generally very fast, and the Form 3 doesn't buck the trend. These times are comparable to other SLA printers like the Peopoly Moai, which took between 7 hours and 20 minutes and 18 hours to produce a similar print.

One thing to note, though: while our tests were done with the standard gray and clear resins from Form, the company offers a special resin called Draft Resin, which can be printed in layers 0.3mm thick. That would make printing significantly quicker, but less detailed. That resin wasn't available for us to test.

Form 3 3D printer review: Print materials

The Form 3 is designed to work with parts and materials only from Formlabs. You have to buy the resin tanks and cartridges from the printer maker. A new resin tank will cost you $149, while a cartridge that contains a liter of resin costs $149 for the standard resin, $175 for the tough resin and $299 for the castable wax resin that jewelers and artists use to create molds.

It is possible to use third-party resin with the Form 3 by filling one of the printer's cartridges with another supplier's, but Formlabs claims that this could void the Form 3 warranty. For reference, we got seven fairly large prints out of a single cartridge of the gray resin, so each print cost about $21.

Form 3 3D printer review: Verdict

The Form 3 is a real plug-and-play 3D printer. We didn't have to do any tweaking or fiddling around to get printing — we just plugged in the Form 3 loaded it up and started printing. The whole process was clean and generally hassle free, which is a lot different from typical SLA printers that require a lot of tweaking, calibration and other fiddling to get good results. The Form 3 just works.

At $3,499 and up, though, the Form 3 is also one of the most expensive 3D printers we have tested, and it is expensive to run. For professionals and anyone else who relies on 3D printing, that won't be an issue. The Form 3 will cost a lot up front, but will be worth it for the easier printing it offers. For enthusiasts and amateurs, it's trickier, as you can get equally good results from a much cheaper printer like the $1,999 Peopoly Phenom if you are prepared to take the time to tweak the printer and develop a workflow for cleaning and hardening prints afterward.

Still, if 3D printing is a critical part of your workflow, you'll be pleased with the ease of use and quality results you'll get by the Form 3.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Structural Packaging Design Your Own Boxes And 3d Forms Pdf

Source: https://www.tomsguide.com/uk/reviews/form-3-3d-printer

Posted by: petersacal1959.blogspot.com

0 Response to "Structural Packaging Design Your Own Boxes And 3d Forms Pdf"

Post a Comment